Our History

The History of Number 1 Mill goes back to 1850, when Alvah Crocker established a mill to cook cotton rags for pulp and manufacture paper on a 70" wide cylinder paper machine. Here, at the headwaters of the Nashua River, a dam was built and the mill was run by hydro mechanical power. A coal fired boiler made steam for drying the paper and driving a steam engine. The mill got light from kerosene lanterns. Thanks to the first rail service that arrived in 1845, the mill could service markets throughout the east coast.

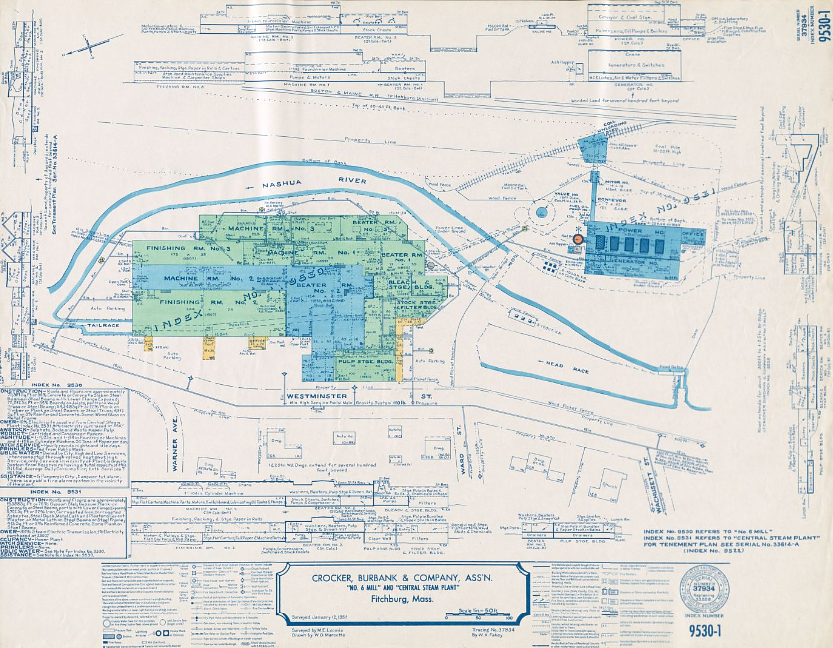

The Crockers took on Charles Burbank as a partner and prospered as the Crocker, Burbank & Company. Wood pulp was invented in the 1880s in Nova Scotia, and the paper industry boomed. Six additional Crocker Burbank mills were built along the river in Fitchburg by 1900, shipping paper products all over the world.

Number 1 mill grew along the way building #2 Paper Machine in 1903, #3 in 1922 and #4 in 1948. The mill made heavyweight grades called Bristols. These paper board grades were used in packaging, office products, automotive parts and art mounting. Support equipment was added as the paper machines were built and the mill footprint grew in 1948 to its present day 253,000 square feet.

Future owners of the Crocker Burbank #1 mill include Weyerhaeuser during the 60s, James River in the 70s and 80s and Fibermark who closed the mill in 2003. The mill had been a consistent money maker for 150 years.

In 2005 the mill was purchased as a warehouse for Can-Am Machinery, a dealer of used equipment for the pulp and paper industry. Can-Am was founded in 1988 down the river, at another former Fitchburg paper mill. By 2000, the industry started to shift. On the one hand, digital technology was shutting down mills dependent on paper as a communication medium, creating a supply of machinery. On the other hand, online shopping created unprecedented demand for paper boxes to ship goods in calling for more mills to make the paper.

Can-Am converted a 1920 vintage pulp warehouse to an office with a great view of the falls that originally powered the mill. An area of 25,000 square feet in the "old end" of the mill was sandblasted and prepped for future uses. The paper machines were sold or scrapped, and buildings were rebuilt for warehouse use. Holes from the machines were filled in, and dozens of concrete piers were removed

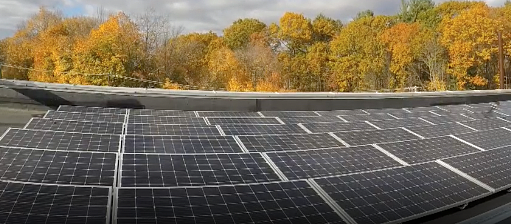

In 2015, a 100 KW solar power system was installed with 335 panels on the #4 machine roofs to provide power for the new layout.

The dream of creating a mill marketplace started to take shape in 2019, with tenants bringing modern-day businesses to the refurbished old mill. Learn more about our tenants, and what our business complex has to offer.